Aqueous Coating for Packaging:

How It Boosts Appeal and Protection

Brands strive hard to create amazing products. For them, their search for effective packaging solutions is obvious. Today, we are offering you a chance to learn about an innovative and great finish option. It is the aqueous coating with its diverse types waiting to enhance your brand. Embrace it to boost your packaging appeal and functionality. Read on to know how this happens.

Leaving lasting impressions is as important as crafting amazing products. Various similar products strike customers while they are walking in a store. However, out of them, only those products cultivate attention whose packaging is not only protective but also distinctive and attractive. To cater to this need, packaging manufacturers introduce many innovations. One among them is the emergence of aqueous coating. It is one of the best types of coating used for packaging.

When various viewers touch a product to explore, what do you think happens to them? Obviously, continuous interaction leads to damaging product appeal and also box functionality. Also, the appearance of fingerprints on boxes affects their market presence. Here comes the savvy role of aqueous coating in printing and packaging. It is known for boosting appeal and protection. Want to know how? Don’t worry. Read this article to get the answer to your query.

What is Aqueous Coating?

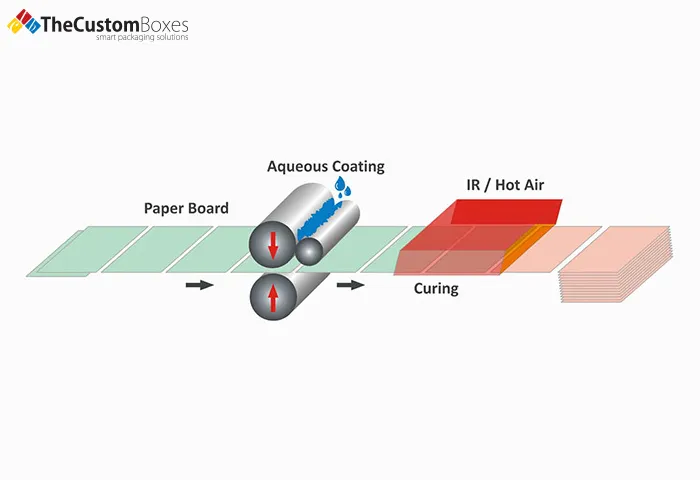

This term consists of two words aqueous and coating. Aqueous meaning is something based on water. Mostly, water-based solutions are called aqueous. To define coating, we can say that it is just a layer or covering. Typically, it is applied on various object surfaces. Its purposes include better aesthetics, improved functionality, and enhanced protection. Coating offers diverse opportunities to the packaging field. One can opt for any of its types including matte, gloss, UV, and many more. Hence, aqueous coating is a water-based coating type. Being clear and fast-drying, this type of coating is largely used for boxes of cardboard, paperboard, or corrugated board.

The non-toxic nature of water makes aqueous coating (also called aq coating) a sustainable and practical choice for businesses. A question may come to your mind: what does aq stand for in chemistry? Well, in chemistry, aq refers to aqueous (a substance that is dissolvable in water). In packaging terminology, aq coating is the same as an aqueous coating. Its application to various products like food packaging, consumer goods boxes, and others. With fingerprint-resistant features, this coating type is best for long-term aesthetic achievements.

The Role of Aqueous Coating in Boosting the Appeal and Protection of Packaging:

Many factors can have bad effects on packaging. These include handling rigors and external factors such as dust and moisture. They can ruin its appeal and put a question mark on their protective abilities. To address both issues simultaneously, aqueous coating (or water coating) is the best solution. Let’s discuss its role in enhancing both aspects one by one.

How Does Aqueous Coating Boost Appeal?

The overall visual appearance of packaging matters a lot in impressing customers. The reason is they interact with the packaging first and the inside product later. See below how aqueous coating works to boost it significantly.

Adds Exclusive and Premium Touch:

Aqueous coating is one of the finest finishing options. They are available in different types. Choosing the most appropriate one for a particular product offers a smooth and polished appeal to the packaging. This elevated packaging look is good at attracting customers and showcasing the premium status of your items. Your selection according to brand style and personality leads to enhancing product appeal up to the mark.

Improves Color Vibrancy:

The aqueous coating is usually employed during printing processes. Thus, print coating serves as a protective layer. It safeguards the printed designs and enhances color tones. With its use, your colored designs and texts pop out and appear sharp. In this way, you can enhance your brand presence by highlighting graphics and brand logos.

Makes Packaging Your Brand Reflection:

Your all desires come true if you use aqueous coating for your packaging. It offers versatility to its users. Being customizable, it allows you to meet your requirements the way you want. Adding a unique and sophisticated touch to the packaging enables you to gain multiple benefits. Thus, you can make packaging that reflects your brand's aesthetics. Customers find it easy to choose you by merely having a glimpse of your product range in a specific packaging style.

Turning packaging into a masterpiece that is hard to ignore is what aqueous coating does. All businesses can experience a major boost in their sales by embracing this option.

How Does Aqueous Coating Enhance Protective Features?

In this competitive business landscape, the visual look of packaging has a significant impact. Brands are investing to make their packaging boxes visually appealing. However, ignoring the basic protective function in doing so is a silly mistake. Looks grab customers while it is quality and functional packaging that retains them for a long time. Aqueous coating caters to both aspects expertly. That is why it is popular among all businesses looking for appeal and protection at the same time. Read on to see its role in enhancing protection of packaging boxes.

Keeping Moisture Away:

Moisture is a dangerous factor that greatly affects the practicality of paper-based packaging boxes. It renders their strength and makes them fragile. Aqueous coating fights with this environmental impact positively. Shielding packaging from moisture, aqueous coating maintains box integrity intact. Moreover, it prevents warping, smudging, or other deleterious effects that can compromise the integrity of the inside product.

Preventing Scratches and Scuff:

Aqueous coating results in the addition of an extra layer. This cover protects the packaging by resisting scratches and scuffs. Otherwise, they may cause wear and tear, leading to product damage. Packaging has to face these factors during handling and transportation. Avoiding them is not possible. So, despite that, try using an aqueous based coating that maintains box integrity and makes it capable of bearing the rigors.

Repelling Grease and Stain:

The food industry and cosmetic industries have to use oil in making their products. Packaging such products is not easy. The risk of box damage due to leakage of oil or greasiness is always high. Also, there is more chance of getting box harm due to unwanted stains. Luckily, the aqueous coating also knows how to handle this issue. It repels stains and grease. As a result, boxes not only remain neat and professional but also functional for a long time.

All these properties of aqueous coating keep boxes protected. Here a question arises: what type of aqueous coating printing is suitable for your product range? Well, continue reading to learn this.

Types of Aqueous Coating:

As already mentioned, aqueous coating holds many types. Knowing them helps you choose an appropriate one for your packaging. Let’s have a look below!

Gloss Aqueous Coating:

Gloss coating is a type of aqueous coating ideal for a louder product packaging appeal. Brands that want enhanced shine in their product packaging prefer glossy coating. You often listen to gloss text vs gloss cover. Both terminologies are common in paper finish options. They differ in their thickness and purpose. The former term finds its application in brochures and flyers while the later one is for business cards and book covers.

Matte Aqueous Coating:

Aqueous matte coating is good if you need a settled touch. It offers less reflection and more readability of printed elements. However, this type is known for providing a high degree of color intensity. Thus, its use allows you to grab maximum customers by properly showcasing design and branding elements.

Dry Erase:

Small businesses with a limited budget should opt for dry-erase aqueous coating. It requires less investment but gives an excellent glossy effect. This type has properties similar to lamination, so it is often used as an alternative to lamination.

Satin Aqueous Coating:

This type of aqueous-based coating provides an intermediate effect between matte and gloss finish. Neither too muted nor too sharp, satin coating is ideal for showcasing elegance and sophistication. Its medium shine allows you to highlight your product features in an excellent way. Moreover, its appreciable scuff-resistant properties permit brands to enhance box protection significantly.

Soft Touch Aqueous Coating:

What is soft touch aqueous coating is often a commonly asked question. As the name indicates, it does not add a sharp shine to the packaging. It gives a soft texture with a velvety texture to the surface on which it is applied. Resembling matte aq coating, soft touch coating is ideal for packaging that needs minimal to no shine.

Final Thoughts:

Aqueous coating is a great packaging innovation. It can serve as a game changer for your brand packaging strategies. Credit goes to its versatility, eco-friendliness, and cost-effectiveness. Moreover, its use allows brands to improve packaging functionality while boosting its overall appeal. Incorporating it allows you to showcase your commitment to innovation and quality. Both aspects lead to brand success and growth beyond the boundaries. So, don’t hesitate to give the aqueous coating a chance. It amplifies your business by contributing to better appeal and improved packaging functionalities. The above-narrated article will help you in this regard. Moreover, choose The Custom Boxes to grab aqueous coating for printing and packaging. We are offering free shipping and customer care services to assist you more.

Frequently Asked Questions About Aqueous Coating

What Is The Difference Between Aqueous And Non Aqueous Coating?

The difference between aqueous and non aqueous coating is quite obvious. Meaning of aqueous is water. Thus, the later coating type is water-based. It is eco-friendly and characterized by quick drying and versatile options. This type of coating is ideal for general applications. Non-aqueous coating is usually a solvent or oil-based coating type. Being durable and more moisture resistant, it offers better protection even under harsh environmental conditions. However, it is less sustainable and may cause difficulty during recycling. Also, it dries slowly.

What Is The Difference Between Matte And Aqueous Coating?

Matte and aqueous coating differs in various aspects. These include differences in functionality, finish type, and applications. Matte coating gives muted and settled packaging appeal. Also, it helps brands to avoid glare as it is non-reflective. Thus, it is good for products that require more protection while maintaining a sophisticated look. This coating type may or may not be water-based. Aqueous coating is a water-based coating type as the word aqueous defines. It is known for offering versatility from matte to glossy and satin.